Pump Shaft Quality

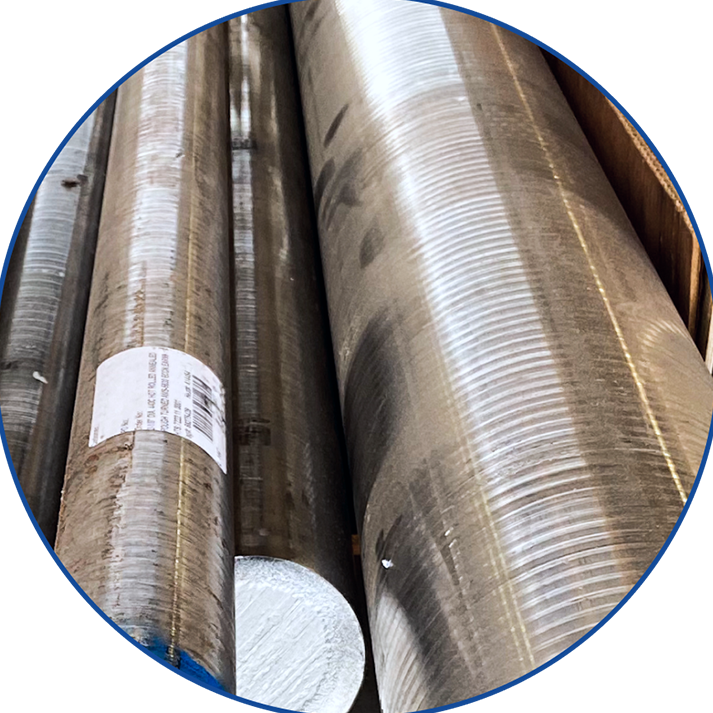

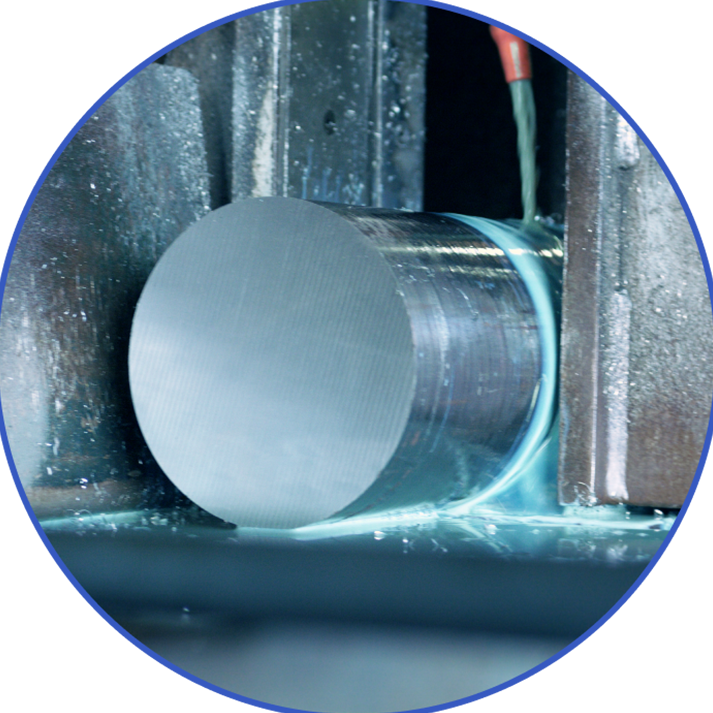

NSA is one of the industry’s leading stocking distributors of pump shaft quality (PSQ) stainless steel and specialty bars. PSQ indicates a turned, ground, and polished shaft used in rotating industries. In this process, the surface of the material is ground down between centers to create a bar with a smoother finish, tighter tolerance on the outside diameter, and a precision straightening of the bar. NSA’s product goes above and beyond industry standards on tighter tolerances which results in a more consistent product and decreases wear and tear. NSA has a unique inventory of grades, sizes, and lengths ranging from ½” RD and up and 20 to 26 feet long in PSQ material. Cut-to-length and custom Outside Diameter sizes are also available. Standard and custom wood boxing is available to ensure the protection of the finish and the straightness of the material during transportation and handling.

REQUEST A QUOTE- 17-4 PSQ

- 316 PSQ

- 410 PSQ

- 416 PSQ

- XM-19 PSQ

- K500 PSQ

- Alloy 20 PSQ

Stainless Steel

Our 300 series stainless steel, including 304 and 316, offers strength and resistance in the toughest environments including the chemical, mining, petroleum, and pulp and paper markets. Additionally, for the highest corrosion resistance, NSA provides 317L to the power generation, food processing, and pharmaceutical industries. NSA stocks multiple heat-treated options of long length 17-4 in desired mechanical properties depending on aging temperature and can be used in rotating equipment, rotor bar applications, marine shafts, oil and gas components, and aerospace parts. NSA also stocks long lengths and sizes with various strength levels in 400 series stainless bar including 410, 416 and 420 and offers a stress-free rotary heat treat option.

REQUEST A QUOTE17-4 (UNS S17400)

- 17-4 Cond A

- 17-4 Cond H1025

- 17-4 Cond H1075

- 17-4 Cond H1150

- 17-4 Cond H1150D

- 17-4 PSQ

- 17-4 Rotor Bar

304/304L (UNS S30403)

- 304 Cond A

316/316L (UNS S31603)

- 316 Cond A

- 316 PSQ

317/317L (UNS S31703)

- 317 Cond A

410 (UNS S41000)

- 410 Cond A

- 410 Cond HT

- 410 PSQ

416 (UNS S41600)

- 416 Cond A

- 416 Cond HT

- 416 PSQ

420 (UNS S42000)

- 420 Cond A

- 422 Cond HT

422 (UNS S42200)

- 422 Cond HT

Premium Stainless

NSA premium stainless delivers even greater strength and corrosion resistance than our other stainless grades. What sets XM-19 apart from other grades of stainless is it has good mechanical properties at elevated and sub-zero temperatures. It also does not become magnetic when severely cold-worked and it has outstanding corrosion resistance in harsh environments such as marine applications. Nitronic® 60 is an all-purpose metal and was originally designed as a wear alloy and is considered to have the best galling resistance of all stainless steels. The Duplex and Super Duplex grades are derived from their mixed microstructure which provides elite protection from corrosion caused by chloride and other aggressive chemical products. Industry applications include chemical, pulp and paper, oil and gas components, and desalination.

REQUEST A QUOTEA-286 (UNS S66286)

- Grade 660 Type 1

- Grade 660 Type 2

Nitronic® 50 (UNS S20910)

- XM-19 Cond A

- XM-19 As Rolled

- XM-19 High Strength

- XM-19 PSQ

Nitronic® 60 (UNS S21800)

- Cond A

Duplex F51 (UNS S31803)

- Duplex Cond A

Super Duplex F53 (UNS S32750)

- Super Duplex Cond A

Super Duplex F55 (UNS S32760)

- Super Duplex Cond A

Nickel Alloys

Nickel alloys are often used because they are corrosion resistant, can withstand high temperatures, have magnetic properties, and tolerate a range of thermal expansion. 718 is often considered the workhorse of the oil and gas industry and can be heat treated to achieve many different strength levels. Nickel 400 is a nickel-copper-based alloy known for resistance to a variety of corrosive conditions including hydrofluoric and sulfuric acid and marine applications involving salt water. K500 is superior to the other nickel-copper based alloys in both strength and hardness. Centrifugal pumps, propeller shafts, pumps, and valves all benefit from the increased levels of protection K500 offers. Alloy 20 offers maximum resistance to acids of all types as well as pitting and crevice corrosion in hostile environments. A cold-worked nickel alloy, C22 HS can achieve elevated levels of strength in the tensile and yield values.

REQUEST A QUOTEAlloy 20 (UNS N08020)

- Alloy 20 Cond A

- Alloy 20 PSQ

C-276 (UNS N10276)

- C-276 Cond A

400 (UNS N04400)

- 400 Hot Rolled, Stress Relieved

K500 (UNS N05500)

- K500 Aged

- K500 QQ-N-286

- K500 PSQ

718 (UNS N07718)

- 718 AMS

- 718 NACE/API

C-22HS (UNS N07022)

- Cold Worked

Marine-Grade

Our marine-grade metals have exceptional corrosion performance in salt water and other wet environments. We offer propeller and rudder shafts for a fixed pitch propulsion system for various types of work boats, pleasure yachts, tugboats, push-pull crafts, and Navy and Coast Guard vessels. These boats operate in open waters and inland waterways. The shafts are exposed to salt water, brown water, and brackish water environments. NSA offers custom sizes and tolerances in marine materials with lengths up to 38 feet long.

REQUEST A QUOTE- AQ 17 (17-4 H1150)

- AQ 19 (304 N)

- AQ 22 (XM-19 HS)

- AQ 25 (2205 Duplex)

- Nickel K500

- ABS GR2